When putting up a structure out of prefabricated parts, one of the first things to do is to seek help from Precast Panel Detailing Services. It’s a very intricate endeavor, and precise execution is still the key to success. Fabricating structures is used again and again as molds for casting concrete members is the main focus of precast concrete steps work.

The experts here at Designing Drafting are motivated by our firm’s commitment to providing excellent client service. We take on benefits from our meticulous attention to detail. Many detailed, modeling, and shop drawing tasks have been completed successfully since our inception.

Thanks to this, we feel quite confident taking on precast projects of any size. Our team has years of expertise in precast detailing. Based on the quality of our services, we have been able to attract and retain customers. To keep ahead of the competition, our professionals only employ cutting-edge tools to complete client assignments.

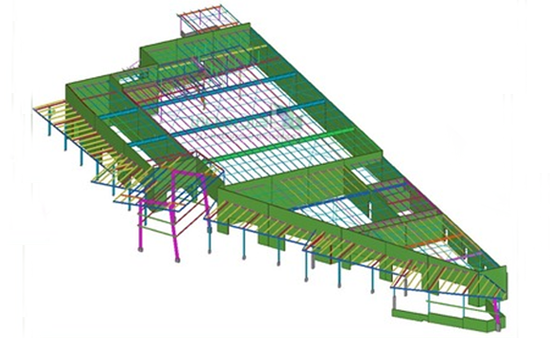

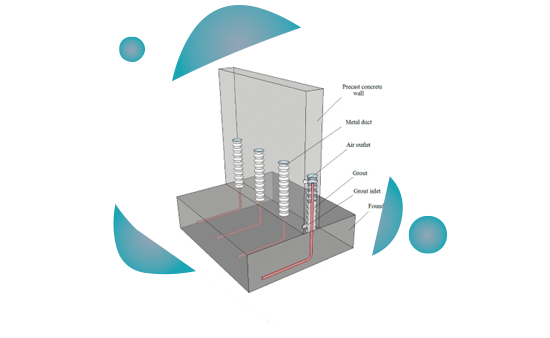

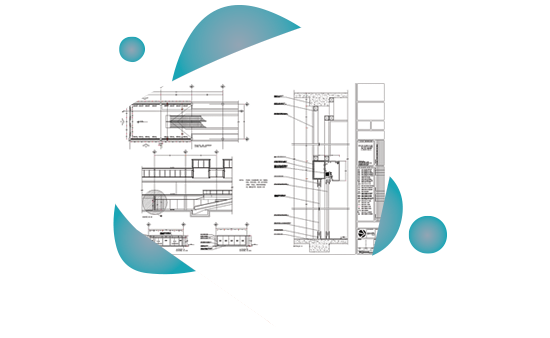

It's no secret that our company is the precast panel detailing service provider in the area. We offer precast detailing services to ensure that we capture all the necessary and appropriate details in the precast panels. Moreover, the detailing services and precast concrete steps include wall panel layout and design, detail design, model creation, as-built drawings, and shop drawings. Therefore, these services are provided by our company in order to meet the building owner's requirements for functionality and aesthetics. Once our experts analyze the 3D model, then they create the plans for each wall panel. Similarly, the plans include all the necessary dimensions for cutting, shaping, and installing each part of the panel. Therefore, this allows for a more efficient production process, which translates into cost savings for you as a client. After that, we gave you a proposal based on the information that you provided us throughout our consultation process.

We offer this service that will be beneficial for the purpose of completing your projects the way you like. Our experts involve in creating an illusion of depth on the surface of the precast panels. We do it so that you can use it for cladding. We do it in a way that it must create a better visual effect for the exterior of your building. As Precast panel detailing may also involve adding other features like concrete steps precast to enhance any existing details on the precast panels. For example, you may want to add a cornice or parapet wall to create an architectural look. You may also want to include some brick patterns onto your precast panels to make them look natural. These added features can help you achieve an expensive detail without spending too much.

It can break the detailing process down into three stages:

Preparation is the first step in the precast panel detailing process. Before we cast it into a mold, the preparation stage includes cleaning, drying, and handling the concrete. Moreover, preparation also includes adding color to the mix and ensuring that there are no voids in the final product.

Once preparation is complete, a detailed design can begin. A detail designer works with a customer to create a custom design for their project by drawing up a plan. Similarly, that drawing shows how each panel should look when finished. This plan will include all necessary measurements needed to ensure that each panel fits together seamlessly when assembled on site.

When the design is complete, it moves on to fabrication where molds are created using computer-aided design software (CAD). These molds are used to cast each individual panel within a larger formwork system that holds all of them in place while they dry. Once cast, all panels must go through curing processes before they can be moved without damage occurring on-site installation. After curing has been completed, we gave each individual panel one final inspection before it is ready for delivery. It is also possible for you to obtain Rebar Detailing Services from us as per your project's requirements.

Precast panel detailing is a fundamental part of the precast manufacturing process and concrete steps precast. Moreover, these can be considered a mainstay in any concrete construction project and are appropriate for use in both commercial and residential applications. The use of precast panels can save time and money during the construction process, as well as increase safety. Precast concrete detailing is a crucial component of the precast concrete design process. It involves the preparation and installation of extruded or cast precast panels that are to be used in buildings or other structures. These panels are usually installed with the help of a crane and using lifting cables, even though there are also small size panels that can be moved manually.

The main reason that makes this process so important is the impact it has on the overall appearance of the structure. Good quality detailing can improve the aesthetics of any building, while poor detailing may ruin its appearance and make it look unattractive. Additional benefits of using precast panels include:

Precast Panel Detailing service is an important part of our architectural service. This is made for extra support for the Precast column's structure, which is often seen in large-scale buildings, etc. Our services include:

We specialize in the following kinds of projects:

We’re the right choice for precast panel detailing service because we offer quality work. We’ll listen to your needs and concerns, and provide you with a detailed quote so you know what to expect. You’ll be able to see our past work samples, along with other useful information such as pricing, before making a decision. Moreover, we also have experience dealing with contractors who use your property as staging areas or storage sites during construction. We understand the importance of keeping your property safe and clean during this time, so we communicate well with them to ensure that happens. Another way is by partnering with local organizations that support youth employment initiatives.

It gives us great pride to give back and makes us effective in our goal of being a neighborhood-focused forterra pipe & precast company. So, hiring our precast panel detailing services is the right decision.