Do not get confused about the importance of 3D assembly drawings in modern industry. In the advancement of the new world, it is clear that you cannot get proper information from 2D assembly drawings. Moreover, you do not need to because, with the help of AutoCAD assembly drawings, you can easily build different Engineering and CAD assembly drawings. However, you must also know the importance of design assembly drawings, which we have discussed in detail. Furthermore, the different fields you are working with are also mentioned in the following, and if you are related to one of those fields, do not under-consider the market potential of different Fusion 360 assembly drawings and other relevant technical designs.

What are Assembly Drawings?

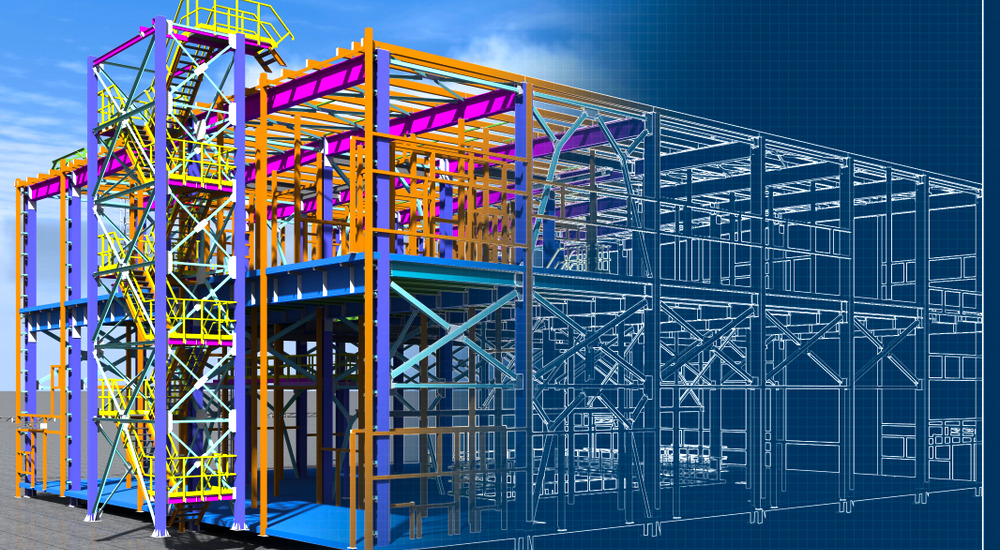

Assembly drawings are the technical drawings of items that may have more than one component. They try to assemble those components in the form of sketches and drawings. They know the placement and identification of each element. Moreover, assembly drawings create 3D CAD using 2D methods to see how multiple points fit together. These drawings rely on orthographic projections and graphic techniques.

Importance in Engineering and Design

While working on large-scale projects, it is essential to see all the project components together to see how they will look after manufacturing. If there are no assembly drawings, you may have to elaborate on the project via speech or writing, which can be time-consuming and a hell of work.

More Clear Visualizations:

With assembly drawings, you will get high-quality visualization of your data. The designer can put multiple components together to see the actual visualization of the project before it even starts. It clearly shows two or more parts of an element or subordinate assemblies. Therefore, GAD provides a clear picture of everything included in the project. This is why all the stakeholders can understand the project visualizations easily without any confusion.

Provide Accurate Drawings

The technique is used for more accurate and high-quality measurements and design of the components. By using a diversity of 3D assembly drawings and 2D assembly drawings, there is less risk of errors in the final documents of the project. The use of CAD assembly drawings and auto CAD assembly drawings reduces the chances of human errors. Sometimes, humans lose some of the essential details while working manually; thanks to AI and CAD, they get everything.

Collaboration and Communication

It enables seamless collaboration and communication between the relevant parties, such as clients, teams, constructors, and stakeholders. While collaborating, sharing your ideas and views on the designs is easy. They can also suggest on-site changes and modifications while collaborating.

Increase the Cost-effectiveness

By providing accurate and effective drawings, it reduces the overall cost of the project. You would not need any changes or modifications during the process. Consequently, there is less risk of repeating any task while working. This means that there would be no waste of resources or any damage to your budget track.

Types of Assembly Drawings

2D assembly drawings and 3D assembly drawings have several types that depend on the type of construction and project you’re working on. Following are some types of assembly drawings:

Solidworks Assembly Drawing

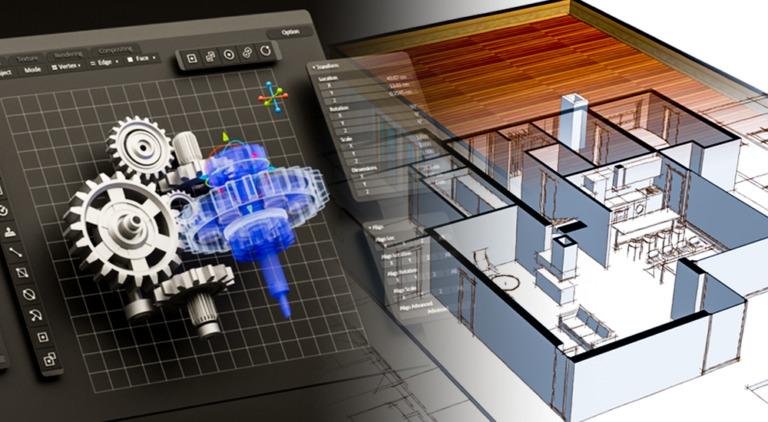

Solidworks assembly drawings are computer-aided modeling designs and computer-aided applications used to develop mechatronic systems. Solidworks can create these systems from start to end. The software can do each relevant task that is necessary for assembly modeling. The task involves planning, idealization, modeling, and featuring the parts of the solid to build SolidWorks assembly drawings. The software generally works for electrical, mechanical, and software component formation.

General Assembly Drawing

They generally identify the different components and their relationship with each other in the drawing. These drawings are detailed in nature, along with sub-assembly and final assembly. Moreover, designers create them during the initial design phase of the project to know how to assemble the several angles of the machine. It gives you information about shape, material, joining method, and components.

Exploded Assembly Drawings

They show the components of the machine slightly suspended or away from each other in the space. Furthermore, the product’s final shape is what you can see on the paper. These drawings are available with manuals, catalogs, and instructions for the product.

Role of AutoCAD Assembly Drawings

When it comes to CAD assembly drawings, you can create them manually or use any computer-aided software, such as Autodesk or AutoCAD tools. AutoCAD overall supports any type of 2D or 3D design. These AutoCAD drawings are useful for different areas, such as:

- In engineering and construction, AutoCAD software prepares several 3D models and 2D Assembly drawings of different product components. It is helpful for the construction to visualize their project in better shape.

- Moreover, an architect in interior design allows the designer to add different layers of interior ideas along with paint and furniture to the final output. It makes the process easy for everyone. These experiments remove the chances of errors in the final product.

- In the product design and manufacturing industry of heavy machines and robotics, it assists the engineers in understanding how the pieces will fit together more properly. This is the fabrication of mechanical parts of the products and robots.

- Furthermore, it is also used to manufacture software tools and packages for different work platforms.

Design Concepts of 3D Assembly Drawing

There can be several design concepts to assemble a product. However, the designers look for more precise and reasonable design concepts for each other. They want to put the final product in a manageable shape. The design concepts depend on different standards, such as the purpose of the product and the target audience. The designer keeps in mind every little detail of the expected outcome of the product and its working expectations in the real world while designing it.

Three-Dimensional Representations

Most designs work with 3D visualization of the product by creating 3D assembly drawings instead of 2D assembly drawings. It is more helpful for the designer because it provides them with extra information on the elevation of the project. However, the drawings require technical skills to build properly.

Enhancing Realism and Clarity

With the 3D factor, the product looks more real and near to the actual real-world shape of the product. This enhances the clarity of the project by adding proper value to it. The user gets a better idea of what the product is actually about.

Role of CAD Assembly Drawing

Assembly drawings are important for several projects and designs in the industry. Moreover, they have become integral to the construction and manufacturing industry. Following we have discussed the role and benefits of CAD Assembly Drawings.

Engineering Assembly Drawing

Civil engineers and other engineering fields use assembly drawings such as robotics, manufacturing, and software building industries in the engineering sector. The technology has become an integral part of each sector. It is only possible to assume the final shape of your product by visualizing it in 3D assembly drawings or at least its rough sketch on 2D assembly drawings.

Part of Computer-Aided Design

It is part of computer-aided design packages. With the help of the latest and more efficient software, it is not difficult to design computer-aided assembly drawings with more accuracy and less risk of human errors.

Top 5 Benefits Importance in Modern Engineering and Design

- Decrease the downtime of the project or any product and help the manufacturers and constructors to complete the project on time.

- Increase the efficiency of the project by allowing the user to interact and understand the project details.

- It lets you see the final output before it is constructed, which means that you can already see the product’s shape and final look, allowing you to demand any changes in the product shape.

- It helps you avoid frustration and unclear roadmap during the manufacturing or implementation. This means that you have a precise plan to go with, which you keep things on track.

- It keeps the company and the customer from any conflict in the future. Because the customer can claim the inefficiency of the final product if it is not similar to the drawings, or the company can defend itself if there is any issue. They can claim that they have made exactly the customer’s demand.

Conclusion:

In the article, we talk about everything related to the assembly drawings. However, you can speak with consultants from different companies if you need clarification about the technology. They can guide you in a better way.